Materials

Seeger retaining systems are manufactured as standard from high-grade spring steels which are best suitable for the special characteristics of the various types. The rings are hardened during heat treatment to enable them to absorb high axial forces when fitted in the groove. Larger rings have a lower hardnesses because the stresses placed on them during assembly are not as high as the stresses placed on smaller rings. The hardness of rings is specified in terms of Rockwell or Vickers hardness. The hardness of rings with a thickness of less than 1 mm can be measured only in terms of Vickers hardness.

Carbon spring steel

The demands placed on the material, such as a high modulus of elasticity, high yield point, high elastic elongation and good hardening abilities, are achieved best by spring steels in accordance with DIN 17222. The material Ck 75, material No. 1.1248 is especially used to manufacture Seeger rings. This is a high-purity carbon spring steel with a low phosphorus and sulphur content. The Materials C 75 in accordance with DIN 17222, Mk 58 and spring steel wire in accordance with DIN 17223 are also used to manufacture Seeger retaining systems.

Special materials

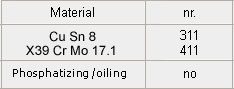

In addition to the above-mentioned carbon spring steels, corrosion-proof materials are also used. The following materials are still used to manufacture Seeger retaining rings:

Tin bronze CuSn8, material number: 2.1020.34, DIN 17662

Tin bronze CuSn8, material number: 2.1020.34, DIN 17662

Although it has a high strength, this material has a lower elastic deformation than spring steel. Rings manufactured from this bronze therefore tend towards plastic deformations in the higher-stress smaller dimensions. However, a stress fit in the groove is almost always guaranteed. In comparison with spring steel, this material's lower modulus of elasticity amounting to 115000 N/mm2 results in a reduction in its load bearing capacity and its detaching speed. Tin bronze is antimagnetic and, even at low temperatures, shows no tendencies towards embrittlement.

Beryllium bronze CuBe2, Material number 2.1247.75

This material has a higher strength than tin bronze after heat treatment. That is to say, just like spring steel it can be worked when soft and then hardened. When hardened, this material has an elastic elongation which is higher than that of spring steel. However, the use of beryllium bronze is restricted by its very high price.

Corrosion-resistant stainless steels

1. X39CrMo17.1 Material nr. 1.4122

As a hardenable martensitic chrome steel, this material does not have the resistance of austenitic chrome nickel steels. This steel suffices for numerous applications and is used above all in the manufacture of smaller and medium-size rings.

2.X12CrNi177 Material nr. 1.4310

This material is an austenitic corrosion-proof stainless steel which is particularly suitable for work hardening. Both Seeger rings to DIN 471/472 with dimensions of more than 100 mm nominal diameter (concentric form) and circlips SW/SB can be manufactured from this material.

Note

Since all stainless steel tend to a greater or lesser extent towards specific types of corrosion which, in certain circumstances, may lead to sudden failure of the ring assembly due to brittle fracture, it is absolutely necessary to pay attention to the specific characteristics of these Materials under the influence of corrosive media when in use.

The risk of stress corrosion can be eliminated by reducing the tension. Therefore the depths of the grooves should be designed in such a way that the rings are fit without or only with a very low pretension.

How to order

Hardening processes

Spring steel components can basically be hardened in accordance with two different processes:

1.Martensic hardening

By quenching from the austenitising temperature (approx. 800-820° C) in oil at room temperature, a martensitic structure is achieved which will attain the required degree of hardness and toughness by subsequent tempering in a salt bath or in air.

2.Isothermal austempering

By isothermic conversion to the bainite phase, the desired structure is achieved with the following advantages:

-extreme toughness and thus higher permanent strength and a reduced risk of hardening cracks and better elimination of stress peaks

-less distortion due to a smaller temperature difference

-less sensitivity to hydrogen embrittlement

-energy saving

Apart from a few exceptions, all Seeger retaining systems are always hardened by isothermic conversion.

Surface finishes

To achieve corrosion protection adequate for storage and transport, most of the rings are zinc-phosphated and oiled. If higher demands are placed on resistance, Seeger retaining systems can be supplied with special surface finishes, which are applied either galvanically or mechanically. In the case of galvanically produced surface finishes, zinc must be given preference over cadmium for pollution control reasons. To improve corrosion protection, chromate treatment is additionally carried out. Use is only made in exceptional circumstances of copper, nickel or chrome coatings. Both during the cleaning and also during the coating processes of galvanic treatment, hydrogen atoms may be absorbed. In certain circumstances, this may lead to a hydrogen-induced delayed brittle fracture. As a rule, the risk of brittle fracture is avoided in Seeger products by means of thorough degasification after the galvanization process, but this risk cannot be excluded completely (see also DIN 267, part 9).

In addition to galvanic surface coating, increasing use is also being made of mechanical plating. In a special process, zinc or tin particles, or mixtures of these, are hammered onto the ring in a drum by means of glass balls of a suitable size.

The standard Seeger-Orbis range contains a large number of galvanized rings to DIN 472 and DIN 6799, and these are available from stocks.

Others surfaces finishes

In addition to galvanic surface coating, increasing use is also being made of mechanical plating. In a special process, zinc or tin particles, or mixtures of these, are hammered onto the ring in a drum by means of glass balls of a suitable size.

The standard Seeger-Orbis range contains a large number of galvanized rings to DIN 472 and DIN 6799, and these are available from stocks.

The following surface treatment processes can also be mentioned:

Electrophoretic painting:

The phosphated surface is additionally protected in a subsequent painting process. This produces outstanding Corrosion resistance. However, the relatively thick coating of approx. 0.04 mm must not be overlooked.

Other processes of surface coating based on hardened synthetic resin and zinc compounds are available on request. All above-mentioned processes necessitate specific batch sizes to be economically justifiable. When using Seeger retaining systems with additional surface coatings, please note that the coating thickness increases the ring thickness, and this must be taken into account when dimensioning grooves. The products' designations include details of the coating material (abbreviated with the coating thickness in µ). The surface protection designations are given after the ring designations. Refer to the Seeger data charts or the Seeger range and price list for further information concerning ring designations.